ماكينة لحام بولي إيثيلين تركي 315مم

ماكينة لحام مواسير وقطع خاصة ( هايدرولك ) القطر من 90مم إلى 315مم الصناعة تركي

- الشحن:

- سياسة الإرجاع: يتم تجربة المنتج قبل استلامه بحالة جديدة وبدون اي مشاكل ولا يحق ارجاع المنتج بعد شرائه الا في حالة وجود عيب صناعة

وصف المنتج

W315 BUTT WELDING MACHINE GENERAL FEATURES

Machine is for weldings of PE – PP – PVDF pipes and fittings up to 32 Bar .Welding sizes are 90 – 110 – 125 – 140 – 160 – 180 – 200 – 225 – 250 – 280 – 315mm

With the shortest setup time it provides simple and fast welding operations according to international standards ISO 12176 – 1

With it’s lightweight nature provides easy handling

Maximum working pressure is 150 Bar

The working environmental temperature is -40 C° ~+40 C°

W315 BUTT WELDING MACHINE FRAME

W315 BUTT WELDING MACHINE FRAME

The trimmer is the tool which cleans and smoothes the both ends of the pipes before the heating process with its blades on both

W 315 Butt-welding machine trimmer unit ensures clean and parallel pipe faces

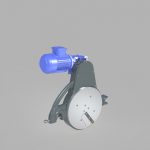

W315 BUTT WELDING MACHINE TRIMMER

W315 BUTT WELDING MACHINE TRIMMER

- The trimmer is the tool which cleans and smoothes the both ends of the pipes before the heating process with its blades on both

- W 315 Butt-welding machine trimmer unit ensures clean and parallel pipe faces

W315 BUTT WELDING MACHINE HEATER

W315 BUTT WELDING MACHINE HEATER

The pipe ends will be heated by this heater before the welding

The settings of the heater will be done by the thermostat on the control

W 315 Butt welding machine PTFE- coated heating element ensures uniform surface temperature.

W315 BUTT WELDING MACHINE HYDRAULIC AND ELECTRICITY CONTROL UNIT

W315 BUTT WELDING MACHINE HYDRAULIC AND ELECTRICITY CONTROL UNIT

The necessary electric will be transfered to the heater and trimmer by means of this unit and to the main machine by the hydraulic

It will be controlled by the manual On the manual control panel there are four buttons and a key. The clamps are controlled by the buttons and the trimmer by the key.

W315 BUTT WELDING MACHINE HOUSING BOX

W315 BUTT WELDING MACHINE HOUSING BOX

– Housing and support box prevents the heat loss of the heater and protects the trimmer from the exterior effects in a manner supporting the heater (against impacts, water, etc.)